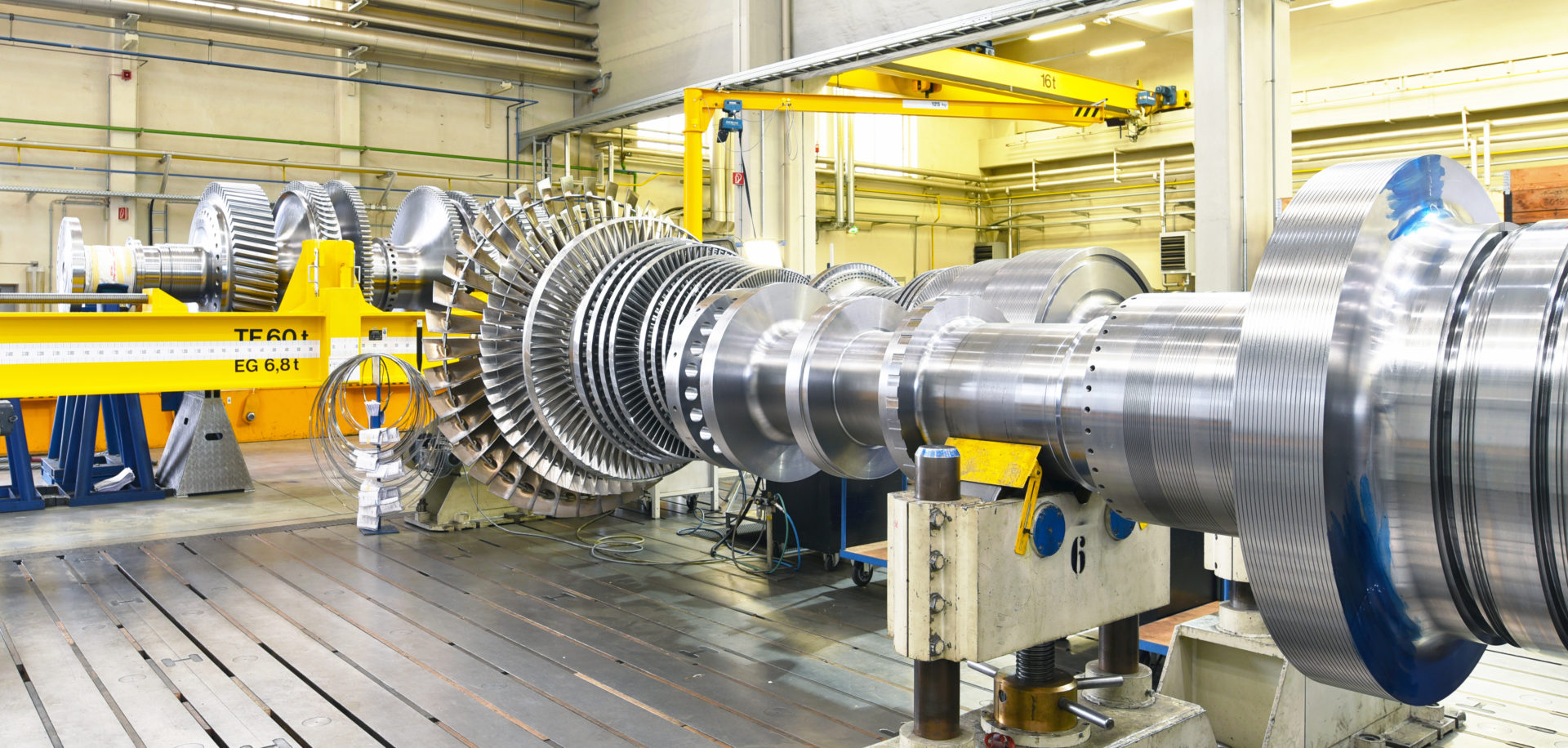

Industrial equipment and heavy machinery are becoming more complex today. The ever-growing tendencies of the Industry 4.0 — big data analytics and cloud storages of complex data, the Internet of Things, engineering automation, etc. — encapsulate groundbreaking alternations in the way industrial manufacturers work and interactions with clients. These new technologies dictate the necessity in foremost and emerging industrial machinery solutions that could support the development, manufacture and supply of complex and powerful equipment and utilities. In this steady rising, companies must innovate and manage complexity. Open Cascade solutions can help heavy machinery manufacturers operate in a complex and demanding environment and cope with unique modern challenges.

Increase productivity and improve manufacturing processes to meet the difficult and challenging conditions of modern industry development:

- End-to-end workflow for manufacturing simulation — enabling fully automated end-to-end simulation workflows results in reduced engineering costs and minimized risk of human errors.

- Collaborative web-based solutions for product design review — well organized planning of product design or production facility maintenance leads to less amount of unexpected costs and delays and faster acceptance of subcontracted work (laser scans, etc.).

- Simulation scenarios in a virtual 3D asset — Open Cascade software has a cumulative effect of risks and costs reduction due to solutions accessibility, 3D democratization and ease of use of simulation scenarios on gas turbines or industrial pumps CAD models.

- Interactive work instructions using 3D models — increased accuracy during assembly or quality control stages becomes possible due to intuitive contextual 3D representation. Streaming of 3D and configuration data to the shop floor and minimization of manual work for work instructions authoring allows drastic reduction of costs and efforts.

- Drawingless shop floor and enhanced maintenance, repair, operations (MRO) — cost saving on MRO can be achieved by the usage of 3D data instead of legacy paper manuals. Reduced error rate during operations and time saving on interactions in downstream processes and documentation costs reduction due to the automation of the authoring processes make Open Cascade solutions to be the best choice for the industry.

- Mastering product manufacturing information (PMI) data for Metrology and Quality Control — Open Cascade software reduces manual efforts spent on set up of measurement and inspection scenarios, improves product quality due to interventions minimizing and allows embedding quality control into digital manufacturing.

- Enabling ‘Quality 4.0’ on a Smart Factory — combining IT and OT in an end-to-end shop floor solution breaks down silos and reduces costs over the entire process. Intelligent matching of virtual (3D) and real-world (measures) data enhances this effect even further by minimizing risks and preventing downtime.