Overview

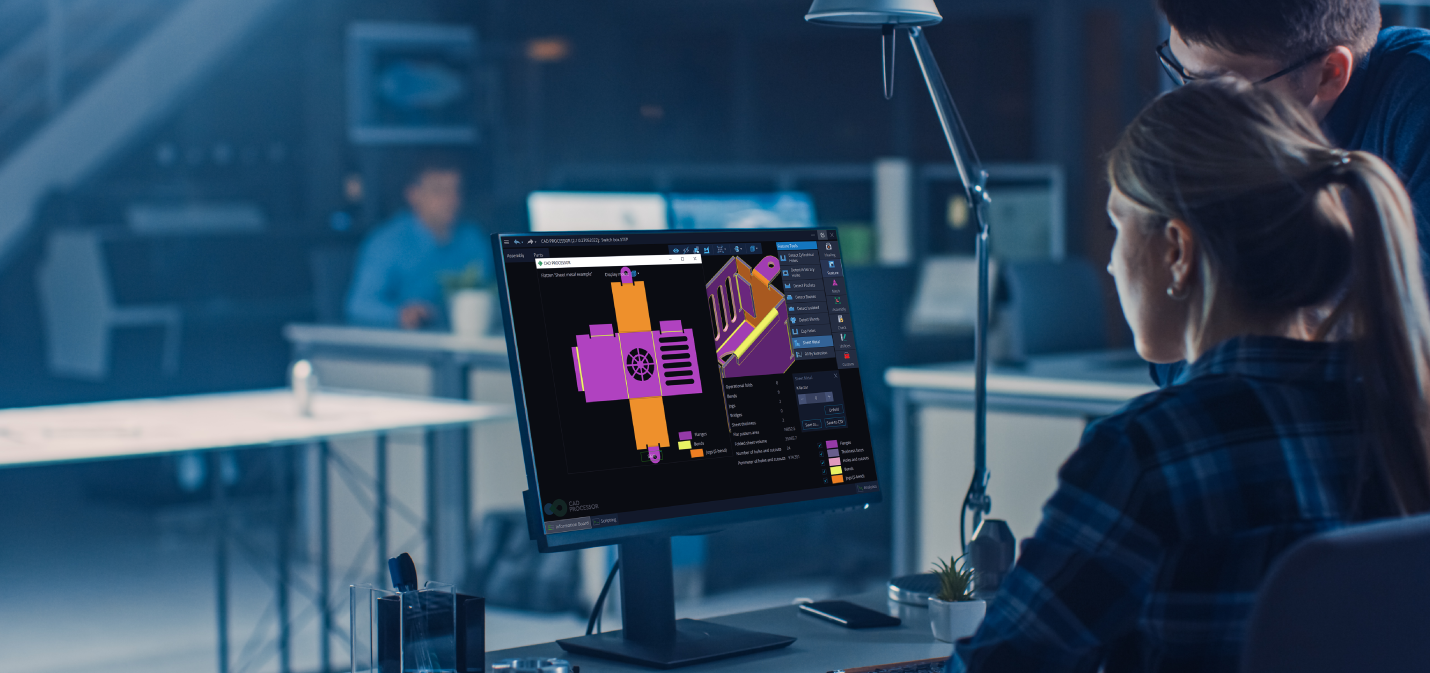

Fabrication of sheet metal parts requires specific algorithms such as unfolding, extracting properties, and drawings generating. This functionality is available with Sheet Metal Operations Component.Besides sheet metal related algorithms this SDK also contains basic data management algorithms and supports assembly-level operations, such as model loading, saving, restructuring, extracting subassembly to file or retrieving information about data node, recognizing canonical geometry, etc. The SDK functionality is available for evaluation with Open Cascade`s end-user product CAD Processor .

Features

- Performs recognition on a given part to detect primary features including flanges, bends, jogs, holes and cutouts to make a sheet metal part ready for unfolding. No construction history is needed for recognition process (dumb geometry). Visualization of features in CAD Processor:

Hole

Cutout

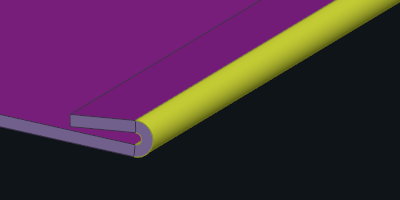

– Bends: standard bends with a pair.

Bend (yellow)

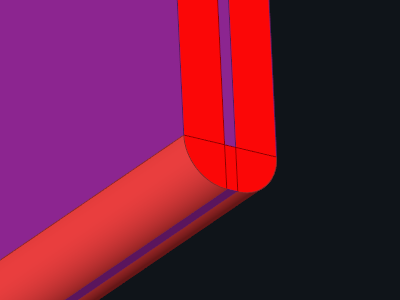

– Abnormal bends: the general term for bends with issues, such as lack of a pair bend, a sharp corner where smooth transition is expected, etc. Includes crushed bends for the purpose of counting.

Abnormal bends (coral red) without inner bends

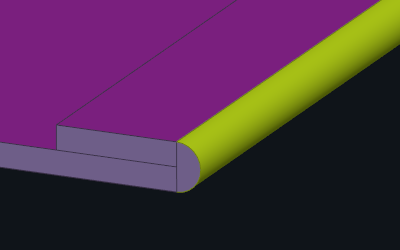

– Crushed bends (hems): 180° bends without a pair, which result in zero distance between sheets.

Crushed bend (yellow)

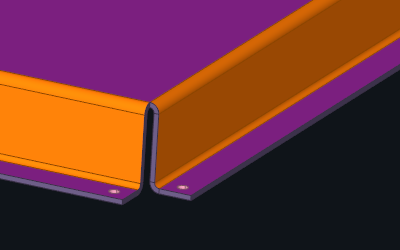

– Jogs (silks): pairs of bends in a zig-zag configuration.

Jogs (orange)

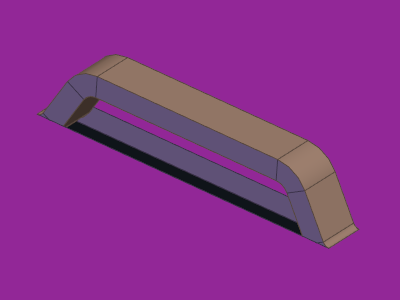

– Bridges: pairs of jogs connected by a planar face.

Bridge (brown)

- Includes properties extraction: – length, rotation angle and radius for bends and operational folds,

- Unfolds the recognized sheet metal parts, builds and validates flat patterns. Well-known k-factor is employed to achieve accurate unfolded plate.

- Prepares data for automated fabricating cost estimation.

- Robust algorithms for sheet metal working operations easily built-in to your application.

- Speeding up the development process and increase of ROI with ready-to-use time-proven development tool that can be applied immediately to your specific environment.

- Plenty of licensing options including annual or perpetual, node-locked or floating licenses.

- Considerable cost saving on development.

- Integration into your application by our experts available upon request within Open Cascade Support services.

- Windows 7, 8, 10, 11,

- Compiler: MSVS 2015 or newer,

- 64 bits,

- Corresponding version of Open CASCADE Technology (at the moment – version 7.6.1).

- Ubuntu 18.04.6,

- gcc 7.5.0+,

- 64 bits,

- Corresponding version of Open CASCADE Technology (at the moment – version 7.6.1).

– mass-inertia properties such as folded sheet volume, perimeters, areas, thickness etc.,

– number of holes, cutouts, operational folds, bridges, etc.

Benefits

Sheet Metal Operations SDK implementation in CAD Processor

Sheet Metal Operations SDK implementation in CAD Processor