Challenge

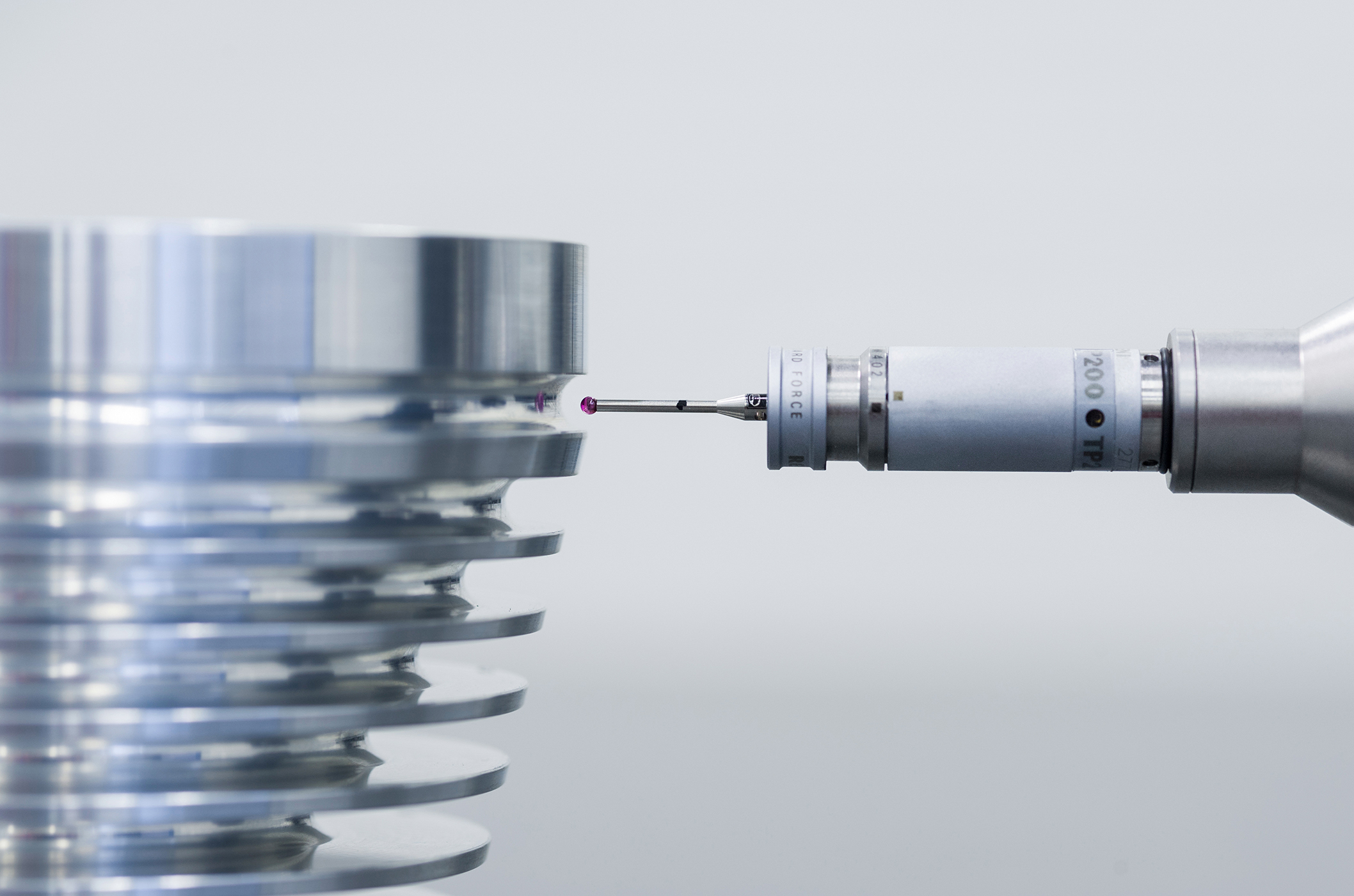

With traditional 2D drawing-based workflows, many tasks are processed manually, stealing skilled engineer’s time for such a common work. Manufacturing and quality control engineers manually enter and interpret Geometric dimensions and Tolerances (GD&T) into their CMM (coordinate-measuring machine), CAM (computer aided manufacturing), or CAI (computer aided inspection) software. Depending on the complexity of the part, it can take days if not weeks.

Using Model Based Definition (MBD) as a new approach to enriching a 3D model with PMI (Manufacturing Product Information) such as dimensions, tolerances, roughness, thickness, notes, requires a new industrial workflow. A 3D model in tandem with PMI can be a holistic tool aiming for the product lifecycle for more effective quality control and iterative assessments.

Technology solution

Open Cascade Commercial Platform unlocks a full usage of semantic product manufacturing information (PMI) contained in a digital product for automated manufacturing and validation workflows through guided data linking and integration mechanisms.

3D data visualization solutions with the ability to display, create and import PMIs allow to obtain data from various third-party software systems or directly from files. PMI entities imported from STEP AP242 (ISO 10303-242), JT format (ISO 14306:2017) and common proprietary CAD formats are aggregated into a single hybrid data store, also known as single source of truth, and associated with the digital model for each object. Open Cascade offers proprietary technology assuring that PMI representations are supported by industry standards for geometrical tolerance are implemented in accordance with ISO 1101:2012 and visualization of GD&T data in a 3D scene is performed in compliance with ISO 16792:2015.

As a part of digitalization, compliant visualization of PMI guarantees digital continuity, ensuring that universal symbols and styles are used for PMI presentations, regardless the origin of the software system.

Business value

PMI plays a significant role by enabling a transition from 2D drawing-based workflows to a 3D model-based workflows, thus providing the next generation of manufacturing processes to minimize risks and reduce efforts.

PMI includes the necessary GD&T, BOM and 3D data and can by automatically consumed by machines and software, therefore saving time and reducing any human error such as interpretation or transcription.

As MBD and its PMI data comes from an integrated and coherent single source of truth in machine-readable format, invalidated engineering changes and unintended deviations are caught earlier in the lifecycle thus reducing scrapped parts, missed deadlines, and most importantly, the unwilling recall of the product from the end-customer.