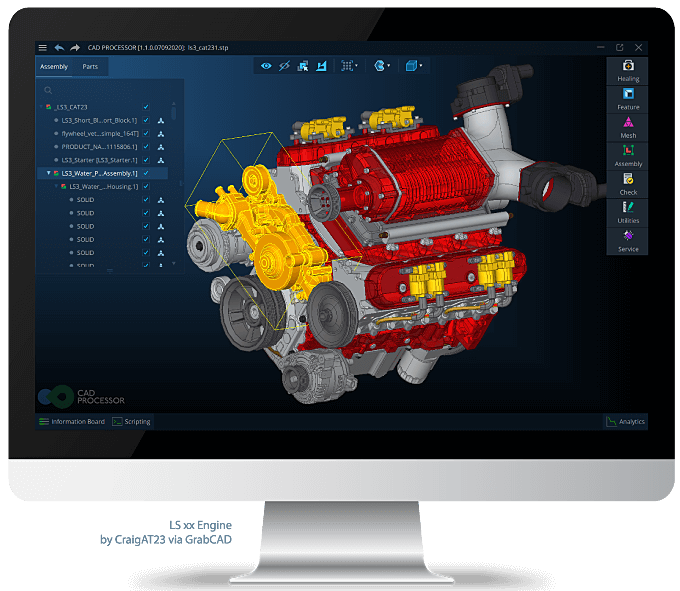

Powerful software dedicated to 3D data preparation and simplification for various downstream applications

Preparation of scenes for Augmented, Virtual and Mixed Reality

Geometry simplification for 3D model visualization on low performance devices

Simplifying 3D data for numerical simulation (FEA mesh generation, CFD)

Intellectual property protection — hiding parts, deformation of details, preserving outer geometry

Quality control — comparison of manufactured part to reference CAD model

Modelling a lightweight digital mock-up of parts or assemblies from heavy CAD files

Restoration and optimization of 3D data integrity for manufacturing

Outfitting design — reference geometry simplification for design processes

Preparation of sheet metal components to fabrication (drawings generating, cost estimation)